1-5t/h Palm Oil Press Extraction Machine Plant In Malaysia

- usage: Palm Oil Extraction

- max capacity: 10-1000TPD

- weight: 10000 KG

- warranty: 2 years

- oil type: Palm Oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 98%

- voltage: 220V/380V/440V

- key selling points: Sustainable

- Product name: 1-5t/h palm oil press extraction machine plant for palm fruit

- Keyword: 1-5t/h palm oil press machine plant

- Raw material: Palm Kernel/plam fruit

- Machine Material: Steel,carbon steel

- Acid value: Less than 1.0mg koh/g

- Residual oil in meal: Less than 1%

- Indine value: 44-46 gl/ 100g

- heating method: Steam heating

- Feature: High Oil Yield Efficiency

- Method to press: Cold Hot Press

- Packaging Details: For palm oil extraction machine plant for palm fruit : Standard international bubble film in container.

- Port: Qingdao/Shanghai/Any port of China

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 20.000 kg

- Supply Ability

- Supply Ability: 300 Set/Sets per Month palm oil extraction machine plant for palm fruit

In recent years, the market of palm oil production in Malaysia is booming. More and more investors find strating a palm oil mill really good business plan, especially in Malaysia and Indonesia. As an professinal and reliable palm oil machine manufacturer and supplier, we always believe that equipment quality is always the heart of one company’s performance. To serve each of our client in the best possible manner on mutually beneficial basis in a long run, we keep treating quality and service as a way of life.

We specialize in the production of various palm oil extraction machine equipment, the main products are small palm fruit oil press, 1-5 tons per hour double spiral palm fruit oil press, 1-10 tons per hour complete set of palm fruit extraction equipment. Palm fruit equipment has been sold to Indonesia, Thailand, Nigeria, Cameroon, Ghana, Cote d ‘Ivoire, Benin, Congo, Burkina Faso and so on.

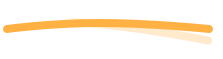

The double screw palm oil press machine is a revolutionary product that offers a wide range of benefits for palm oil producers. Its advanced features, such as low palm nut breakage, minimal oil residue, flexible moisture content requirements, and high – capacity production, make it a top choice for efficient and sustainable palm oil extraction. With its excellent workmanship, compact structure, stable operation, and low maintenance requirements, the double screw palm oil press machine is a reliable and cost – effective solution for the palm oil industry.

Double Screw 1-5T/h Palm Oil Press Oil Mill Manufacturer Palm Oil Pressing Line Oil Processing Plant

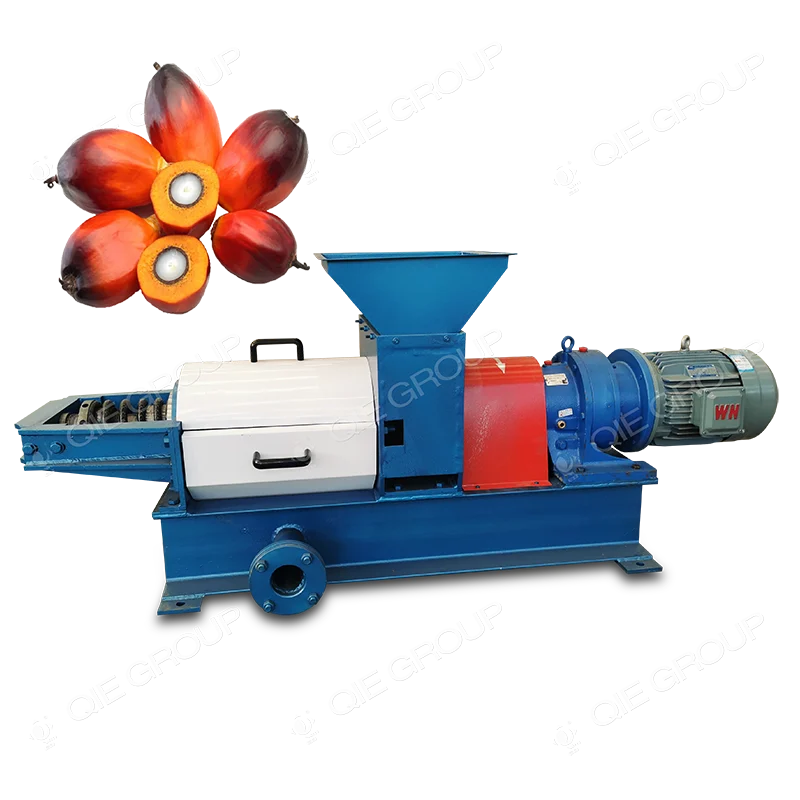

The flow chart process of palm oil processing machine palm oil milling plant:

FFB(Palm fruit bunches)–Sterilizing–Thershing–Digesting–Pressing–Clarifying–Filtering–Drying–Crude palm oil

1-5t/h Palm Oil Press Extraction Machine Plant In Malaysia

The different types of milling are based on the output and how complex the process will be.Today the use of machines has been adopted to replace the traditional methods which are outdated.The latter method is tedious and time consuming.The process of extraction of the palm oil is by the use of solvent extraction methods.

The following process of manufacture is used to produce quality palm oil as indicated below in a stepwise manner:

Palm fruit preparation

After the fruit is harvested ,it’s mainly taken to the processing area mostly within 48 hours.Upon arrival to the processing area ,it is weighed.the quality of the fruit is checked at this point.

Sorting out the fruit

The nest step involves thrashing to separate the bad from the good ones,The palm fruit is given the right type of moisture awaiting the next stage.

Sterilization

The fruit must be sterilized by the means of a high temparatures,The fruit can also be sterilized by the use of hot water There are some fruits which are sterilized by cooking which mainly serves the following objectives:

- It helps to destroy enzymes ,thereby minimizing oxidation and hydrolysis.

- It helps to soften structure of the pulp making it easy for them to digest.

- The moisture obtained while boiling is used to break gums and resins.

Digestion

This is where the palm oil is obtained from the fruit which breaks down the oil cells. The processing may be done either manually or chemically.

Features of palm oil processing machines production line:

1 Compact and strong structure, and easy operation.

2 The automatic control system which can adjust barrel pressure.

3 High oil pressing efficiency, and residual oil in cake is less than 8%.

4 Low crushing efficiency for palm nut.

5 Invest is small, quick gains.

Our 1-5t/h Palm Oil Press Extraction Machine Plant Advantages

This palm fruit oil press machine mainly used to extrude palm fruit oil, cost recovery soon.

Suitable for small farm about 3-15 hectares,or self-employed businessmen who process the incoming materials as well as for home use.

Easy operation, easy move, easy change place. Driven by motor.

Popular in Africa, South Africa, South America, Cameroon, Thailand, Ghana, Nigeria, etc.

| Crude Palm Oil product scheme | |

| crude oil moisture content | ≤0.1-0.2% |

| Impurity content of crude oil | ≤0.2% |

| Palm kernel moisture | ≤ 8% |

| Husk content of palm kernel | ≤2.0% |

Palm Oil refining: crude oil – degumming & dephosphorization – deacidification – drying – decolorization – deodorization – defatting – dewaxing – finished oil.

Oil refining can remove mechanical impurities, solute fat impurities, pigments, moisture and other impurities in the oil, and then to produce pure high-quality edible oil.

With the ever increasing world population ,leads to the increase in demand of the palm oil and associated products, Indonesia is perhaps the world’s best palm oil producer ,followed by Malaysia. Palm oil production in Malaysia is a major economy in which the government assists the citizens with subsidies to help them increase production of palm oil.The demand of palm oil all over the is projected to increase due to the rapidly growing population.

The palm oil can be used for various uses in the industries which include:it is used to make hair products,used to make edible oils plus other soaps.

Palm oil production is vital for the economy of Malaysia, which is the world’s second-largest producer of the commodity after Indonesia. The Malaysian Palm Oil Board (MPOB) is a government agency responsible for the promotion and development of the palm oil sector in the country. The country’s palm oil industry produces about 90 million tonnes of lignocellulosic biomass, including empty fruit bunches, oil palm trunks, and oil palm fronds, as well as palm oil mill effluent (POME). In 2010, in response to concerns about the social and environmental impact of palm oil, the Malaysian government pledged to limit palm oil plantation expansion by retaining at least half of the nation’s land as forest cover.

| 10-500T/H oil material first cleaning, drying and storage section turnkey project. | 30-1000T/D oil continuous grade one or two physical (chemical) refining production line. |

| 20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turnkey project. | 10-200T/D Fatty acid esterification production cooking oil production line. |

| 1tph-120tph palm fruit processing line and palm kernel processing line. | 250TDP shea nut pressing, 100TDP oil refining and oil fractionation Nigeria equipment. |

| 300TPD soybean pre-treatment and solvent extraction plant and oil refinery Egypt plant. | 50TDP palm oil refinery and fractionation plant and oil filling machine Ghana. |

| 300TDP cotton seed pretreatment, solvent extraction and oil refining equipment Kazakhstan. | Two sets 50TPD oil refining production line Pakistan. |

Packing & Delivery

Company Profile

HENAN QIE MACHINERY CO.,LTD — Qie Group is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R &D and application of new technologies.

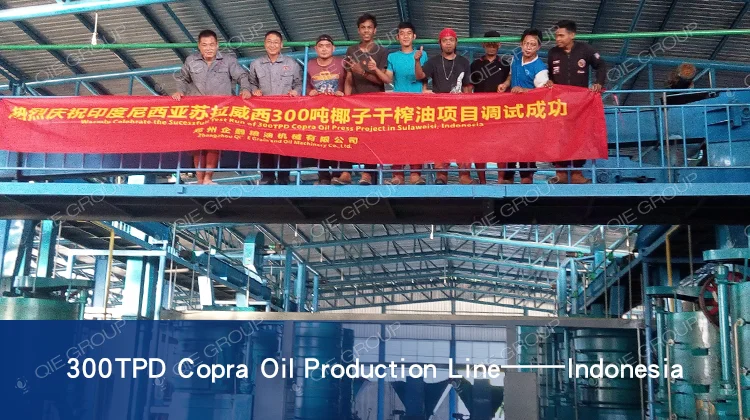

Customer Photos

- What machines are used to make palm oil?

- The list of palm oil processing equipment

Simple palm fruit thresher.

Screw palm oil press machine.

Plate and frame filter machine.

Sterilizing tank.

Palm fruit thresher.

Horizontal and vertical digester.

Palm oil press machine.

Machines used for oil clarification section. - How do you extract oil from a palm tree?

- The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

- What machinery is used for palm oil?

- Its list of palm oil processing equipment mainly consists of a simple thresher, an oil press and a plate and frame filter. These machines can meet your basic production needs. 1. Simple type thresher: it is used for separating palm fruit from palm fruit bunches in palm oil processing process.

- Which country import palm oil from Malaysia?

- India, Pakistan, Bangladesh and Afghanistan are the top importers of Malaysian palm oil in this region, accounting for 96% of total Malaysian palm oil exports to the region.

- What is the process of palm oil production?

- The steps in palm oil production process is divided into sterilization, threshing, digesting, pressing, oil clarification and filtration. If you want to get RBD palm oil, there is also degumming, deacidification, decolorization, deodorization four steps refining process.

- What is a palm oil mill?

- Palm oil mill process includes 6 parts: Palm fruits receiving, sterilizing, threshing, digesting and pressing, crude oil clarifying and palm kernel recovery. Our palm oil mill process is low cost and energe-saving.

- What is the issue with palm oil in Malaysia?

- In recent years, Malaysian palm oil has faced significant scrutiny and discrimination in global markets. This backlash often stems from concerns about environmental sustainability, deforestation, and social issues related to palm oil cultivation.

- Is Malaysia the largest producer of palm oil?

- Malaysia is the second leading producer of palm oil worldwide, supplying around a third of the world’s palm oil.