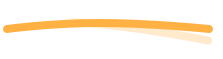

1-5t/h Palm Oil Production Line Palm Oil Processing Machine in Cameroon

- usage: Palm kernel oil refining machine

- max capacity: 10-100TPD

- weight: 10000 KG

- warranty: 1 Year

- oil type: Palm Oil

- type: Cold & Hot Pressing Machine

- automatic grade: Automatic

- production capacity: 98%

- voltage: 220V/380V/440V

- key selling points: High Productivity

- Product name: Palm oil extraction and processing machine

- Keyword 1: Palm kernel oil refining machine

- Keyword 2: 1-5t/h palm oil processing machine

- Raw material: Palm Kernel, palm fruit, crude palm oil

- Machine Material: Steel, carbon steel

- Application: Edible oil production plant

- Acid value: Less than 1.0mg koh/g

- Residual oil in meal: Less than 1%

- Indine value: 44-46 gl/ 100g

- Function: Degumming Dehydration Dephosphorization Deacidification Deodorization

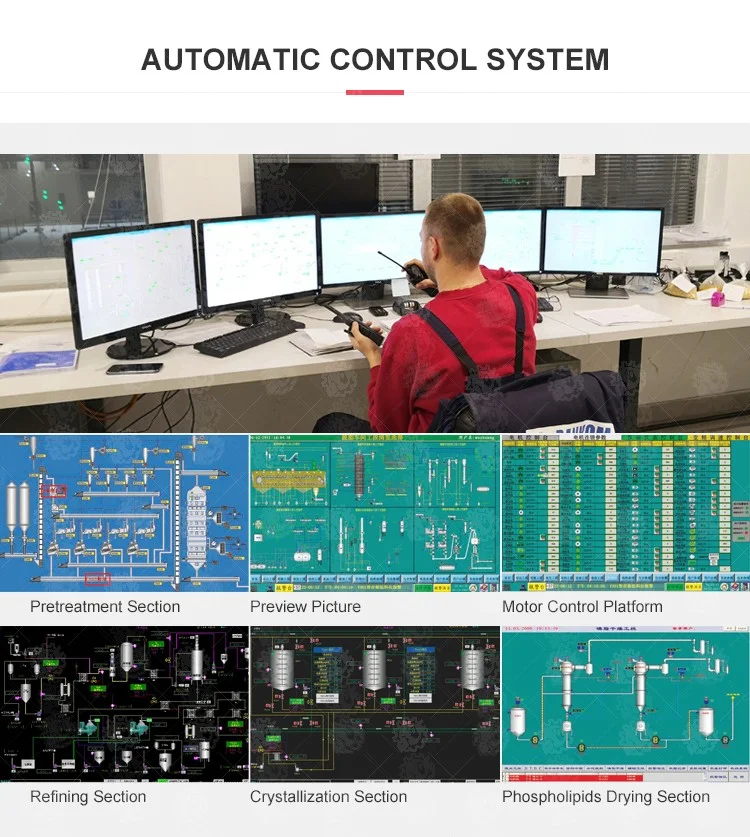

- Packaging Details: For palm oil extraction and processing machine: Standard international wooden boxes in container.

- Port: Qingdao/Shanghai/Any port of China

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 20.000 kg

- Supply Ability

- Supply Ability: 300 Set/Sets per Month palm oil extraction and processing machine

1-5tph complete set palm oil processing machinery is newly and specially designed by QIE GROUP. 1-5tph small scale palm oil processing machinery adopts international advanced and mature palm oil extraction technology to extract palm oil. It is suitable for small palm oil mill and palm oil production business. What’s more, this kind of palm oil processing machinery with low cost and high production rate..

The flow chart process of 1-5t/h Palm Oil Processing Line Plant Machine:

FFB(Palm fruit bunches)–Sterilizing–Thershing–Digesting–Pressing–Clarifying–Filtering–Drying–Crude palm oil

1.Receipt of fruit : Automatic metering and unloading of materials, increase the production efficiency. The fruit cage pushes and pulls along the fixed track and operates mechanized, saving time and effort.

2.Sterilization : Sterilization can be divided into two types, one is a horizontal sterilizer sterilizing tank and the other is a vertical sterilizer sterilizing tank. In comparison, because the horizontal sterilization takes up a large area and the steam consumption is large, it is a relatively traditional sterilization method. The vertical sterilization is based on the improvement of horizontal sterilization. It consumes less, saves resources, and is used more and more widely

3.Threshing: The purpose of threshing is to separate the oil palm fruit from the fruit string by strong rotational vibration. The fruit removal equipment is a drum type fruit remover. The separated oil palm fruit is discharged into the press section. The empty fruit string is discharged from the other end of the drum to the yard or transported to or from the factory area for recycling of palm orchard cover, or on-site incineration as a fertilizer applied to the farmland. The adjustment mechanism of the fruit remover can adjust the delivery speed of the ear.

4. Digesting: The palm fruit masher is suitable for the smashing of cooked palm granules, so that the heating and humidifying mashing effect before the squeezing is better, the squeezing oil yield is effectively increased, and the squeezing process is reduced in the subsequent squeezing section. Walking oil.

5. Oil Pressing: With advanced continuous double screw palm fruit oil press, hydraulic automatic control system that can adjust the pressing pressure, high oil extraction efficiency, low residue of cake residue and low breakage rate of palm kernel.

6. Clarification: Separation of major impurities (such as silt, fiber, etc.) in the oil by means of natural sedimentation

7. Vacuum Drying: As the fresh palm fruit contains moisture, and it also enters a lot of moisture during the cooking and fermenting stage, so when the palm oil squeezed out , it contains a lot of water. If it is not dehydrated promptly, the palm oil will quickly deteriorate and spoil. and the palm oil dehydration equipment uses vacuum heating to quickly dehydrate palm oil.

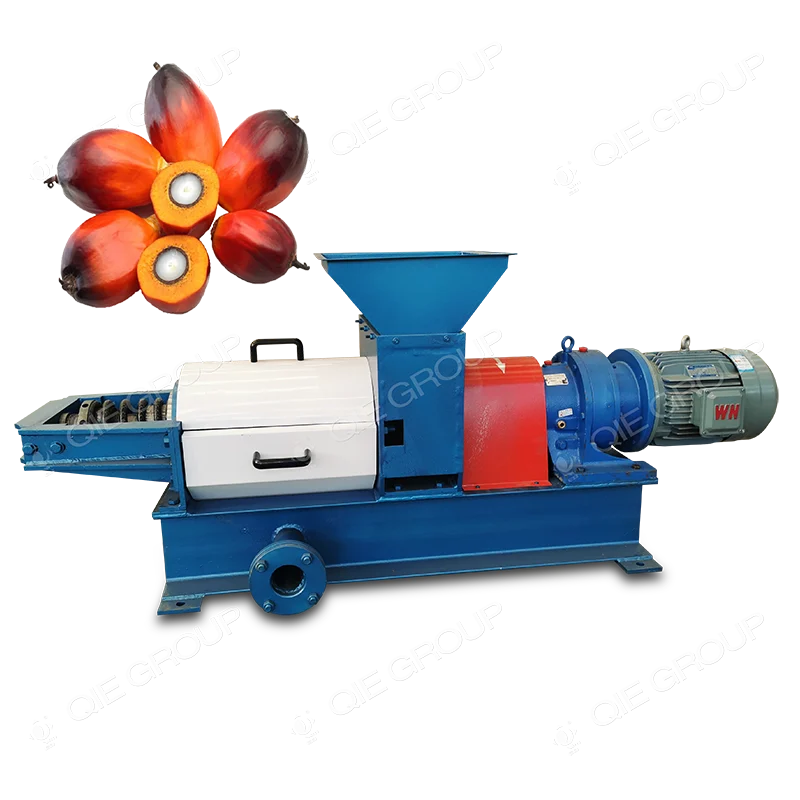

The 5t/h palm kernel oil processing machine ordered by Cameroon customer includes an automatic control system, a cooker, a palm kernel oil presser and palm nut sheller and cracker. Cameroon customer purchased this set of equipment for secondary pressing. For one pressing, the Malaysian large oil press was selected with a residual oil rate of 10%-14%, while our oil press machine has a residual oil rate of 6%-8% and is cheaper. So Cameroon customer chose our palm kernel oil processing machine for further pressing to increase oil output.

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems. If the amount of goods to be delivered is relatively small, the goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Overseas Cooking Oil Production Line

| 10-500T/H oil material first cleaning, drying and storage section turnkey project. | 30-1000T/D oil continuous grade one or two physical (chemical) refining production line. |

| 20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turnkey project. | 10-200T/D Fatty acid esterification production cooking oil production line. |

| 1tph-120tph palm fruit processing line and palm kernel processing line. | 250TDP shea nut pressing, 100TDP oil refining and oil fractionation Nigeria equipment. |

| 300TPD soybean pre-treatment and solvent extraction plant and oil refinery egypt plant. | 50TDP palm oil refinery and fractionation plant and oil filling machine Ghana. |

| 300TDP cotton seed pretreatment, solvent extraction and oil refining equipment Kazakhstan. | Two sets 50TPD oil refining production line pakistan. |

Company Profile

HENAN QIE MACHINERY CO.,LTD is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R &D and application of new technologies.

Customer Photos

- What is the palm oil supply chain?

- The palm oil supply chain can involve many steps: from plantation to mill, then to refinery for further chemical processing and manufacturing, and finally to the products we use every day. The oil palm fruit, above, grows in large bunches that hang from the Elaeis guineensis tree which originated in West Africa.

- What is the production process of palm oil?

- The oil winning process, in summary, involves the reception of fresh fruit bunches from the plantations, sterilizing and threshing of the bunches to free the palm fruit, mashing the fruit and pressing out the crude palm oil. The crude oil is further treated to purify and dry it for storage and export.

- Which Country is the largest manufacturer of palm oil?

- Indonesia is the world’s largest producer of palm oil, producing 44 million tonnes in 2023-24.

- What is the difference between palm oil and palm olein?

- Palm oil is semisolid at room temperature (25–30°C) and can be fractionated into palm olein (liquid fraction) and palm stearin (solid fraction). Palm olein contains higher levels of total oleic acid (39–45%) and linoleic acid (10–13%) compared with palm oil (16). Physically, it is clear and colorless at 25°C.

- Who buys the most palm oil in the world?

- India, the leading importer of palm oil worldwide, imports most of its palm oil from Indonesia. India’s imports of palm oil from Indonesia are about five million metric tons annually, which amounts to approximately 43 percent of its total palm oil imports. Another quarter of India’s palm oil imports come from Malaysia.

- Does Cameroon produce palm oil?

- Industrial production of palm oil is not new to Cameroon. The first commercial plantations were established in 1907 under the German colonial administration in the coastal plains, around Mt. Cameroon and Edea.

- Which company produces palm oil in Cameroon?

- Today, nearly 41% of Cameroon’s palm oil comes from the Socapalm plantations (La Société Camerounaise des Palmeraies). The future of this company, which is located in remote rural areas, is closely linked to the sustainable development of the local population and the local economic fabric.