Small Scale and Large Scale Crude Palm Oil Refining Machine Plant

- usage: Palm Oil Refining Machine

- max capacity: 51-1000tpd

- weight: 50000 KG

- warranty: 1 Year

- oil type: Palm Oil

- type: palm oil refining machine

- automatic grade: Automatic

- production capacity: 5-1000TPD

- voltage: 220V/380V/440V

- key selling points: High Productivity

- Product name: Crude palm oil refining machine plant

- Raw material: Crude palm oil, palm fruit oil

- Keyword 1: Crude oil refining machine

- Keyword 2: Palm kernel oil refining machine

- Machine Material: Stainless Steel

- Capacity: 1TPD-1000TPD

- Function: Refining Crude Oil

- MOQ: 1 Set

- Certification: CE/ISO9001

- Character: Professional Manufacturer

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 20.000 kg

Crude oil refining is an important part of edible oil manufacturing. Oil refining machine can remove mechanical impurities, solute impurities, pigments, moisture, and free fatty acids in grease. Our oil refining machine is suitable to all kinds of oil, eg: rice bran, palm, sunflower, soybean, sesame, rapeseed, peanut, cotton seed, corn germ, walnut, almond, castor seed etc.

The crude palm oil refining machine is designed to refine palm oil which comes from the palm oil extraction workshop. Crude palm oil refining machine suitable for both small scale and large scale palm oil mill plant.

1. Machine type: crude palm oil refining machine

2. Material: crude palm oil

3. Capacity: 1-1000tpd

4. Application: high efficiency palm oil refining machine with low power consumption and high oil quality

Batch Oil Refining Process (1~30 ton/day)

This line of an oil refinery is perfect as a mini or small-scale palm oil mill plant. It requires low investment capital and a smaller occupation of land. You are able to refine almost every type of crude edible oil. The primary refinery process includes three stages which are de-gumming, neutralizing, bleaching, and deodorizing. This process eliminates all the impurities which make the oil inedible.

The refining process also includes making the oil palatable and rancid-resistant if and when it is stored for long periods of time. Batch oil refining holds a capacity of 1TPT to 30TPD.

Degumming: the process to remove gelatinous impurities within crude oils by chemical or physical methods is called degumming. In edible oil, if the content of phosphatide is high, it is easy to blister, smoke and smell when heated. And the phospholipid is oxidized at high temperature and then make the crude oils in dark brown, which affects the flavor of fried food. Based on the principle that phospholipid and some proteins within the crude oils are soluble to oils at the condition of sewage, but insoluble in oil and water after the formation of hydrate, degumming process is to add hot water or steam into crude oils, and heat crude oils, agitation mix at the temperature of 50 ºC. Then let stand for layered, in that way, the phospholipids and part of the proteins are removed from the crude oils.

Deacidification: the Free Fatty Acids (FFA) contained in the oils will affect its stability and flavors. The process to remove FFA is called deacidification or alkali refining.

Decolorizing: crude oils may contain chlorophyll, carotenoid and other pigments. Chlorophyll is photosensitizer, which affects the stability of oil, while other pigments can affect the appearance of oil. So theses pigments can be removed by adsorbent in decolorizing process

Deodorization: there are some undesirable odor substances in oil, mainly from oil oxidation products. The method of vacuum distillation was used to inhibit the oxidation.

Semi-Continuous Oil Refining Process (10~50 ton/day)

This line is suitable for medium-scale palm oil refining factory which are efficient in accommodating clients requests. You are able to refine different types of crude oils as well as plant and animal oils. It has a capacity of 10TPD to 50TPD.

Continuous Oil Refining Process (over 30 ton/day)

This line is specifically for large-scale palm oil refinery. It operates automatically with the refinement of the oils with the utmost efficacy. lts daily capacity stands at over 30TPD.

General introduction of crude palm oil refining machine:

1. Physical deacidification assures low consumption. Crude palm oil refining machine adopts physical deacidificaiton process. It enables low palm oil loss in operation.

2. High efficiency bleaching. The addition of 90℃ phosphate and special rocky soil fulfill perfect decolorization of palm oil with high oil purity and brightness.

3. Deodorization and bleaching achieves final refined palm oil. Deodorization tank removes odor by heat under vacuum The blenching process finally gets refined palm oil at 33℃.

Palm oil refinery

Photos of crude palm oil refining machine :

Specification

| Palm kernel oil processing machine crude palm oil refining machine plant | |

| Machine Type | Cooking oil refining machine |

| Automatic Grade | Automatic |

| Production Capacity | 1-1000TPD |

| Voltage | 220V/380V/440V |

| Crude Oil type | Palm Oil |

| Machine Material | Stainless Steel Oil Refining Machine |

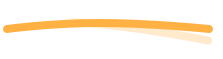

Customer Case

Customer Feedback

Customer Photos

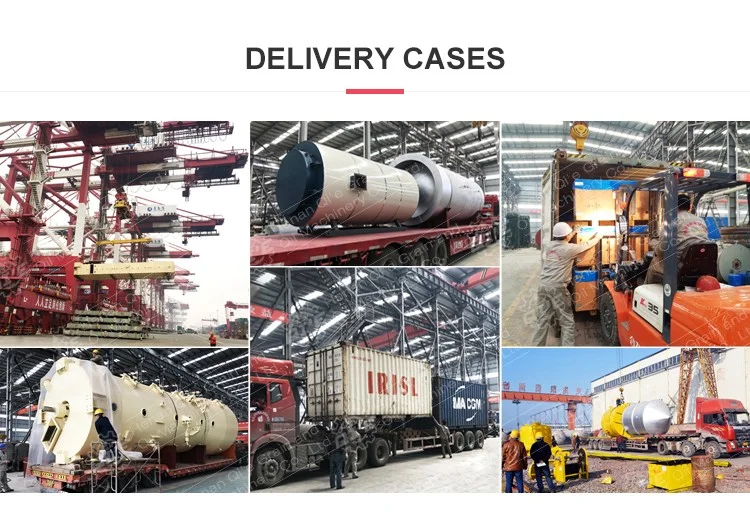

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems. If the amount of goods to be delivered is relatively small, the goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, the goods will be directly loaded into the containers and cut and reinforced to prevent the goods from colliding.

Company Profile

HENAN QIE MACHINERY CO.,LTD is a manufacturer of edible oil making machine, and founded in 1976 with well-equipped testing facilities and strong technical force. With good quality, reasonable prices and stylish designs, our products are extensively used in edible oil production and other industries. Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

- How is palm kernel oil refined?

- Palm kernel oil refining process is an extremely complex process. The palm kernel oil refining process includes degumming process, deacidification process, decolorization process and deodorization process.

- Which is better palm oil or palm kernel oil?

- Saturated fat boosts “bad” LDL cholesterol and triglycerides, both of which are risk factors for heart disease. Palm oil, which is 50% saturated, has a more favorable fatty acid composition than palm kernel oil and coconut oil, which are more than 85% saturated.

- What are the two types of palm oil?

- Two types of oil can be produced; crude palm oil comes from squeezing the fleshy fruit, and palm kernel oil which comes from crushing the kernel, or the stone in the middle of the fruit.

- What is the process of refining palm oil?

- The main process of palm oil refining processes are: degumming & deacidification , decolorization and deodorization.

- What is the difference between crude palm oil and refined palm oil?

- The difference between crude palm oil and refined palm oil is that crude palm oil is the oil that is extracted from the fruit of the oil palm tree, while refined palm oil is the oil that has undergone further processing to remove impurities and improve its quality.

- How do you refine high quality palm oil?

- In order to meet edible standards, crude palm oil needs to go through a series of processes. It mainly includes four steps of degumming, deacidification, decolorization and deodorization.