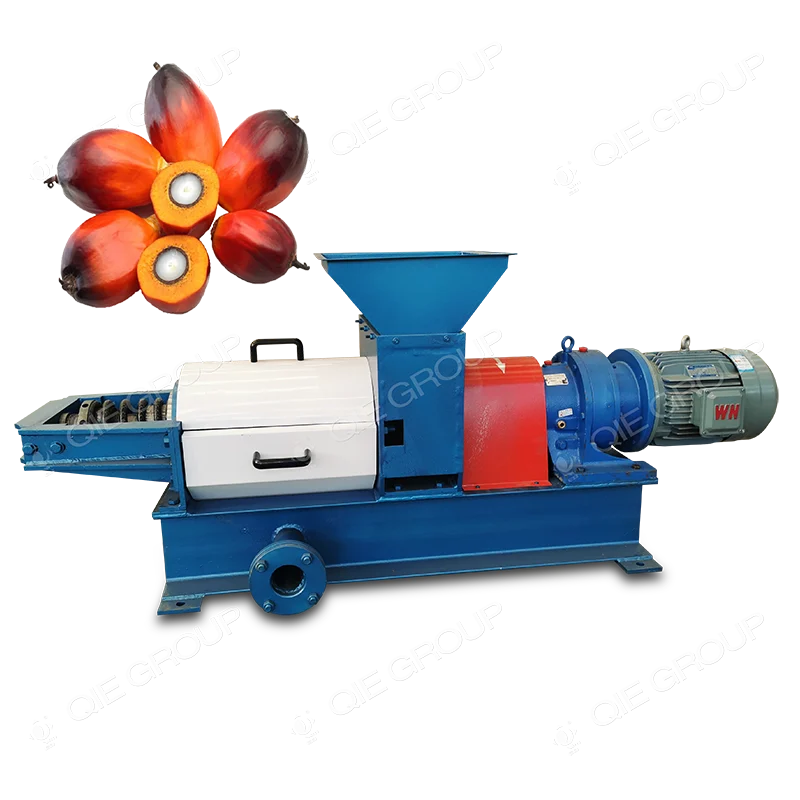

Industrial Palm Oil Processing Machine Palm Kernel Oil Extraction Machine in Zambia

- usage: diesel palm oil processing machine

- max capacity: 1000 kg/h

- weight: 880 KG

- warranty: 1 Year

- oil type: Palm Oil

- type: Cold & Hot Press Machine

- automatic grade: Automatic

- production capacity: 90%-95%

- voltage: 220V/380V/440V

- key selling points: Low Noise Level

- Product name: Palm oil processing machine palm kernel oil extraction machine

- Keyword: Diesel palm oil processing machine

- Machine Material: Steel, carbon steel

- Raw materials suitable: Palm Fruit, palm nut, palm kernel

- Capacity: 100-1000kg per hour

- Press type: Hot Press Oil Machine

- Color: Customer Required

- Package: Wooden Case

- Item: Screw Press Oil Machine

- Character: Easy Movable

- Packaging Details: For china palm kernel oil extraction machine: Standard international bubble film in container.

- Port: Qingdao/Shanghai/Any port of China

- Selling Units: Single item

- Single package size: 20X50X60 cm

- Single gross weight: 20.000 kg

- Supply Ability

- Supply Ability: 3000 Set/Sets per Month china palm kernel oil extraction machine

Palm oil is very famous around the world as a cooking ingredient. In Zambia, it is used to make several local dishes. This oil is also a raw material for the manufacture of several other products such as margarine, cosmetics, soaps, and lubricants.

Palm oil can be processed manually or with the help of machines. If one plans to go into commercial processing of palm oil, it is imperative to invest in the right machines. This means that you need to find out the prices of the machines needed. In this post, we will discuss some of the popular machines on the Zambian market and their prices.

There are three variations of mechanical kernel oil extracting procedure: direct screw pressing, partial pretreatment and complete pretreatment.

- Direct screw-pressing: Some small palm kernel oil mills is designed without any pre-treatment machines. The kernel is fed directly into the oil presses, crushed and compressed at the same time in the oil pressing machine. Double pressing is suggested to achieve higher oil extraction rate. Direct screw-pressing is suitable for small scale oil mill with capacity less than 10 tonnes per day.

- Partial pre-treatment: The kernels are crushed to small fragments before oil expelling. Cooking is also carried out in some cases.

- Complete pre-treatment: The full pre-treatment processes including cleaning, crushing, flaking and cooking are carried out before oil pressing. Large oil mill plant with capacities between 50 ~ 500 tonnes per day choose this kind of kernel oil processing procedure. Palm kernel oil combined with fresh palm oil mill plant adopts complete pretreatment procedure.

The following principles must be followed when selecting Palm Oil Processing Machine:

- The palm oil production process requirements must be satisfied. The selected palm oil mill machine, production capacity, technical parameters, the number of units etc. should meet the production requirements.

- The selected palm oil milling equipment on sale should have high production efficiency, low energy consumption, a reasonable and compact structure, occupying little space and ground, low operating labor intensity, easy to use, maintenance, cleaning, installation, safe and reliable.

- The palm oil processing equipment should meet the requirements of safety, fire and explosion prevention, high temperature, corrosion resistance, etc. of the oil and grease plant, and not to produce pollution to the product.

- The palm oil milling line should be considered as far as possible to use supporting, continuous, high degree of automation equipment.

- For some key failure-prone equipment, the reserve of spare parts and substitute equipment should be given due consideration.

- The palm oil production line structure design should be reasonable, the materials used can adapt to various working conditions, there is a reasonable control system in terms of temperature, pressure, vacuum, concentration, time, speed, flow, liquid level, counting and monitoring of parameters such as procedures, and try to use automatic control methods.

Red oil is made by the fresh palm fruit string, each string is 10kg to 20kg. The fruit string should do the high temperature cooking. Threshing the fruit for the string, heating and pressed by our palm oil press can get red oil with water.

Product Parameter

Product parameter of Industrial diesel palm oil processing machine palm kernel oil extraction machine

| Model | YZX15 | YZX16 | YZX20 | YZX25 |

| Capacity | 300kg/h | 500kg/h | 1000kg/h | 2000kg/h |

| Power | 4KW | 5.5KW | 7.5KW | 11 |

| Heater | 2KW | 3KW | 3.3KW | 3.8KW |

| Temperature of feedstock | 90-95℃ | 90-95℃ | 90-95℃ | 90-95℃ |

| Oil production rate(%) | ≥90 | ≥90 | ≥91 | ≥91 |

Packing & Delivery

Any special requirement of shipping, please talk with us, we will help you to solve the problems.Small goods will be packaged in the form of export wooden boxes. If the goods are shipped in the large quantities, will be directly loaded into the containers and reinforced to prevent the goods from colliding.

Company Profile

HENAN QIE MACHINERY CO.,LTD is a large-sized joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. Our company has been in long-term cooperation with Research Institute of Machine Design Company of Henan, Henan University of Technology (formerly the Zhengzhou Grain College) school-enterprise cooperation in the oil equipment, protein extraction, phospholipid extraction, etc. R &D and application of new technologies.

Customer Photos

Overseas Cooking Oil Production Line

| 30-1000T/D oil continuous grade one or two physical (chemical) refining production line. | 250TDP shea nut pressing,100TDP oil refining and oil fractionation Nigeria equipment. |

| 50TDP palm oil refinery and fractionation plant and oil filling machine Ghana. | 300TPD soybean pre-treatment and solvent extraction plant and oil refinery egypt plant. |

| Two sets 50TPD oil refining production line pakistan. | 20-3000T/D sunflower oil, rice bran oil, corn germ oil dewaxing turnkey project. |

| 10-200T/D Fatty acid esterification production cooking oil production line. | 10-500T/H oil material first cleaning, drying and storage section turnkey project. |

| 1tph-120tph palm fruit processing line and palm kernel processing line. | 300TDP cotton seed pretreatment,solvent extraction and oil refining equipment Kazakhstan. |

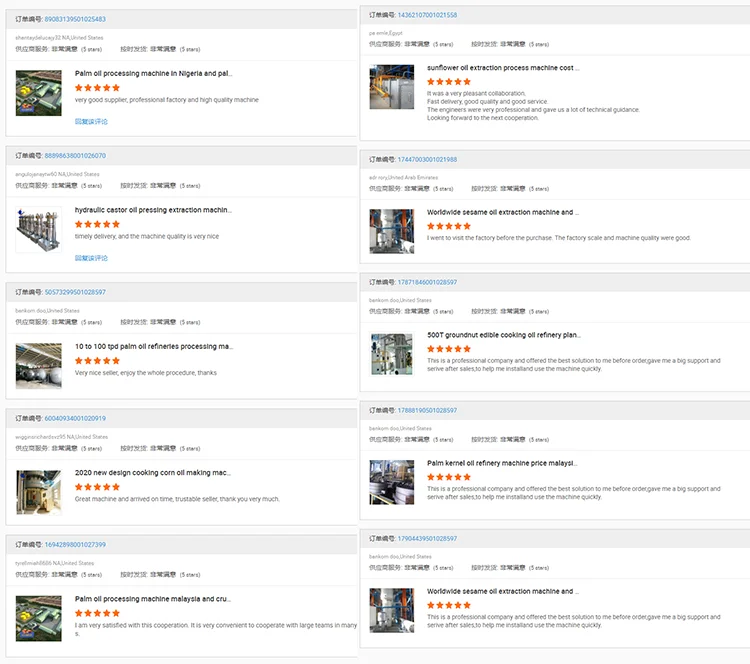

Customer Feedback