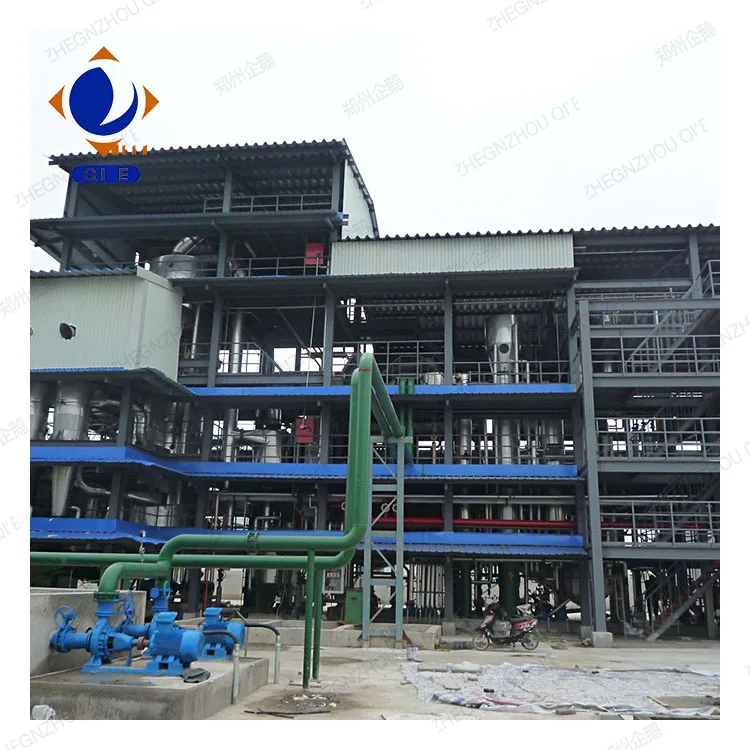

Corn Germ Oil Machine Plant Corn Germ Oil Processing Machine in India

- usage: Pre-treatment, extraction, refining

- max capacity: 10-1000tpd

- weight: 1000

- warranty: 1 Year

- oil type: Corn oil, Corn Germ Oil

- type: Turnkey Corn Oil Project

- automatic grade: Automatic

- production capacity: 88 Sets Monthly

- voltage: 380V or 440 V

- dimension(l*w*h): Depends On Capacity

- key selling points: High Safety Level Corn Germ Oil Project

- Name: Corn Germ Oil Processing Plant Machine

- Function: Making Edible Oil

- Application: Oil Production Line

- extractor type: Rotocel Extractor

- Usage: Corn Germ Oil Machine Plant

- capacity: Corn Germ Oil Machine Plant

- Equipment Material: Stainless Steel or Carbon Steel

- Raw Material: Corn Oil ,Palm Oil Cake,Sunflower Seed,etc

- Extractor System: Toasting System

- Use: Corn Oil Processing Machine

Corn Germ Oil Machine Plant Corn Germ Oil Processing Machine in India

A brief introduction to corn germ oil processing machine

1.The pretreatment process of corn germ oil processing machine

Cleaning: remove most impurities from the material, such as stones, dirt, etc., to prepare for the next crushing process, improve crushing efficiency and extend machine life.

Crushing: after the crushing process, the material is broken into small pieces, which improves the efficiency of the material being pressed.

Softening process: Increase the moisture content and temperature of the material, and ultimately increase the final oil output of the material.

Flaking process: the material is pressed into pieces in this process to increase the amount of oil discharged from the material.

Oil press: the treated oil enters the squeegee from the hopper.

Under the condition of high pressure, the embryo is continuously pushed inward by the screw press, and is pressed to finally produce oil.

| Residual oil in cake | ≤5% |

| Handling capacity | 500kg-50tons/h |

| Crude oil moisture and volatile matter | ≤ 0.30% |

| Power consumption | ≤ 15KWh/T |

| Steam consumption | ≤120Kg/T (0.8MPa) |

| Mechnical impurities | ≤ 0.3% (adjustable) |

| Moisture in crude oil | ≤ 0.2% (qualified detonated experiment |

2.The extraction process of corn germ oil processing machine

(1) The material (for pretreatment) is sent to rotary extraction by the scraper conveyor. The material will extracted by the solvent or mix oil. After this step, we will get meal and mix oil.

(2) Meal is sent to toaster. Through the toaster, the solvent in the meal will separate from the meal. The solvent goes to condenser and is recycled to rotary extraction.

(3) After the mix oil from the rotary extraction enters into 1st evaporator and 2nd evaporator, most of the solvent in the mix oil is separated.

(4) The mix oil from 2nd evaporator goes to stripping tower and almost all the solvent is separated. From the stripping tower, we can get crude oil and solvent. The solvent is sent to condenser and is recycled to rotary extraction.

Extraction→DTDC→Evaporation→Stripper→Crude oilExtraction:

The solvent enters the material and extracts the oil inside the material under a certain temperature and pressure.

DTDC: It consists of seven layers. In the first three layers, the wet mash is heated and heated by indirect steam to pre-dissolve and remove a large amount of solvent. In the next two layers, stripping is carried out under the action of direct steam, the sixth layer is dried with hot air, and the seventh layer is cooled.

Evaporation: The difference between the boiling point of the oil and the solvent is used to separate the solvent and the oil.

Stripper: The separated solvent can be dissolved in the selected paraffin or solvent and recovered.

The extraction operating principle of corn germ oil processing machine

(a) At a certain speed, the material is transported clockwise, and the solvent enters the material counterclockwise, so that the solvent and the material can be contacted to the greatest extent, and the oil yield is improved.

(b) In DTDC, in the evaporation stage, the solvent is evaporated as much as possible, and the solvent is recycled to recycle. Then in the stripping stage, the amount of solvent in the final oil is less than the local specified amount.

(c) The most important thing in the whole process is to control the temperature. Because the boiling point of the solvent and oil are different, so the temperature is controlled, then the quality of the obtained oil will be very good. Do the work of exhaust gas generated during the process of recycling and leaching to protect the environment.

Result of oil slovent extraction

| Moisture of extraction material | 5-8% |

| temperature of extraction material | 50-55°C |

| oil content of extraction material | 14-18% |

| thickness of extraction cake | less than 13mm |

| powder porosity of extraction material | less than 15% (30 mesh) |

| solvent | national standard No. 6 solvent oil |

| volume of supplement water | 1-2m/t raw material |

Introduction of corn germ oil processing machine A general term for a series of processes for removing solid impurities, free fatty acids, phospholipids, gums, waxes, pigments, odors, etc. contained in vegetable oils. Enhancing the nutritional value of edible oils has great benefits for human health.

The refining flow chart of corn germ oil processing machine

Parameters of oil refining machine

| Steam consumption | 450KG/T oil |

| Electric consumption | 28Kwh/T oil |

| Phosphoric acid | 2~3 kg/T oil |

| Circulating water cooling water yield | 150m³/H |

| Bleaching earth consumption | 5~50Kg/T oil |

| Waste bleaching earth oil content | <35% |

| Deodorization loss consumption | ≤0.5% |

The refining process of corn germ oil processing machine

1. Deacidification and degumming

This step is mainly to remove the excess acid in the grease. If the peptized impurities of the oil are not removed, the excessive emulsification will occur during the alkali refining process, so that the oil soap can not be separated well, affecting the refining and Oil quality. When decolorizing, the colloid will cover part of the active surface of the decolorizing agent, so that the decoloring efficiency is lowered, the temperature is higher when deodorizing, the colloid is carbonized, and the color of the grease is increased.

2. Decolorization

The decolorization process greatly enhances the oxidation stability of the oil, and this process also has a great influence on the subsequent deodorization process of the oil. In this process, the oxide is completely removed, and the trace amount of metal, residual soap and residual fat are removed in a maximum amount, and a part of the pigment is moderately removed.

3. Deodorization

Deodorization of oil and fat not only removes odor substances in oil, but also improves the smoke point of oils and fats, improves the flavor of edible oils, and effectively improves the safety of oils and fats.

4. Filteration

Miscella mixed by oil and clay from bleaching tower is pumped into decolorizing filter, then enters into fine filter, in which clay and fixed impurities are blocked.

5. Dewaxing process

Bleached sunflower seed oil enter into crystallizing tank through heat exchanger and begin the cooling crystallization process, this process is controlled by the computer through the parameters preestablished, the computer controls temperature of circulating water in the frozen coil to comand cooling speed of the oil, thereby receive the best crystal result.

Packing & Delivery

The Advantages

(a)Residual oil rate in the dry meal is low.

(b)Improving the quality of the oil.

(c)Low processing cost, high labor productivity.

(d)High automatic and labor saving.

And more other advantages please contact me now, we will provide profession program for you, and we accept custom according your requirements.

Company

Zhengzhou Qi’E Grain&Oil Machine Co.,Ltd is a large-sized joint-equity enterprise which specialize in producting edible oil mechanical equipment, corn oil making machine and it is aslo a group enterprise integrating scientific research, manufacturing,sales as one.Our oil making machine are exported to more than 30 countries,and regions such as Russia, India, South Africa, Ukraine, Nepal, Indonesia and so on.

1. More than 30 years of experience

2.Top production team

3.High quality products

Our Customers

The production and comprehensive economic indicators lie in forefront of the same industry, with products selling all over the county and exporting to over 40 countries, such as Russia, South Africa, Ukraine, Nepal, Indonesia, Kazakhstan, Korea, Vietnamese, Pakistan, Romania, and Serbia, etc.

Regards Quality As The Company Life, Regard Customer As The God, Mutual Benefit And Win-Win Situation With Integrity Tenet.

Honest, Dedicated And Sincere Cooperation!